Incline Impact Test Machine For Product Package Impact Test With ISTA Standard

Features

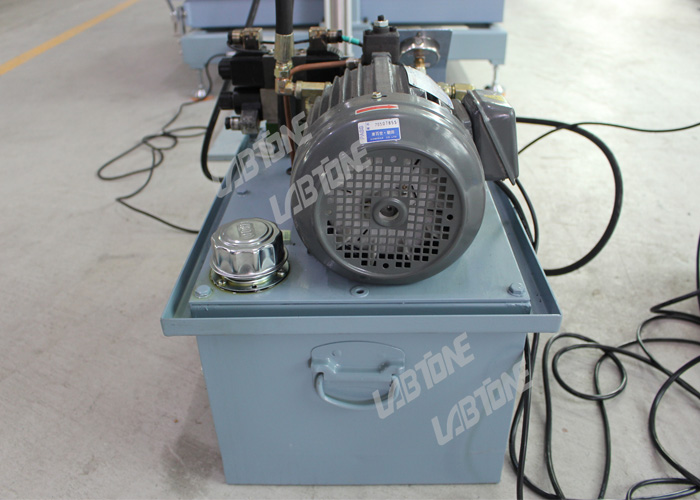

■The system is operated pneumatically, fast operation, safe and reliable.

■ The angle between the guide surface and the horizontal level is 10°.

■ Perfect protection device and safety interlock device to ensure the safety of the operator.

■ Accept special customization, additional installation speed measuring device, provide accurate impact velocity measurement.

Product Application

Inclined impact tester is simulated the impact strength of packaging in the real circumstance of transportation, for example, the transportation of goods. This product is applied to the scientific research institutions, colleges, packaging technique test centers, packaging material manufacturers and foreign trade or transportation departments.

Specification

| Model | IPT-300 | IPT-500 |

Max. Payload | 300 KG | 500KG |

Max. Impact Velocity | 2.1 m/s | |

Tolerance of Shock Distance | ±3% | |

Max. Size of Specimen | 1200*1200*1600 mm | |

Sliding trolley | 600×550×2500 mm | |

Impact base size | 1800*2000 mm | |

| Power | 3phase 380v 50/60Hz | |

Standards | JB/T6868-93 ISO2248-1972(E) | |

Corporate Culture

We hope:To provide the best solutions rather than selling products.

Management idea:Technical research and development as the foundation,integrity-based,survival on quality, service to win customers.

Our vision:To be the well-know manufacturer in the industry of environment and reliability test equipment, and win the respect and trust from customers around the world.

Our mission:To provide the most advanced technology and the most reliable environmental testing equipments to customers.

Core competitiveness:Profession, Quality, Service, Innovation.

FAQ

How do you attach the hardware you’re testing to your shaker?

By means of a fixture, usually aluminum or magnesium for lightness coupled with rigidity. They can be cast, or smaller fixtures machined from solid stock. Most fixtures are welded.

How do you control shakers?

If we’re looking for resonances in the product we’re testing, we command the shaker to shake the product at one frequency at a time but to vary that test frequency, to sweep it over a range of frequencies.But more realistically, we command the shaker to vibrate randomly and to excite all the resonances simultaneously.Control commands go into the keyboard of a specially-programmed computer.

What are those resonances?Are they bad?

Have you ever noticed the steering wheel moving with rather large displacement amplitude, larger than the input to the column? That magnification is called resonance. Possibly it annoys you. There’s a slight chance that in a few years that whipping of the steering column might cause bending fatigue failure.When we shake an automotive or ship or land vehicle instrument, we're looking for, for example, portions of printed wiring boards (PWBs) responding with greater motion than we're inputting. That flexing may damage PWB wiring, it may damage the attached components, and it will damage the soldered connections between components and the PWB.

Product Detail