CE standard half sine shock testing systems for aerospace impact testing

Product description

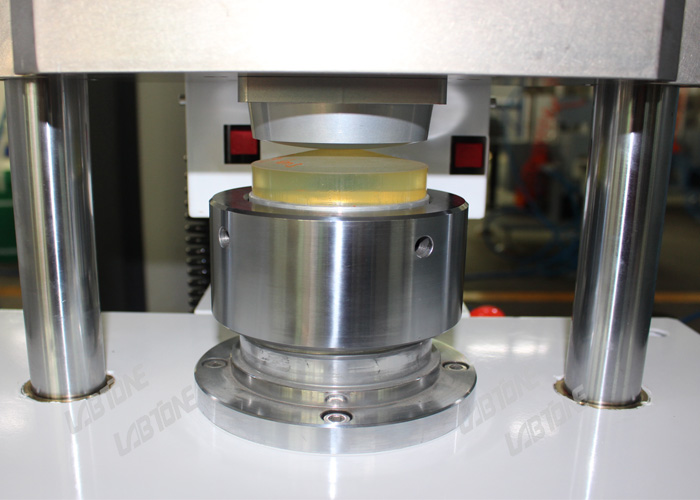

The precise-type high-acceleration shock tester can provide all half-sine short wave specification specified in JESD22-B110. To meet them, merely change different shock rubber-pad on shock seat. The wave is complete with high repeatability, able to provide user accurate test result.

Conform to different test specs such as JESD22-B110 and IEC spec.

Product Features

- All operation accomplished automatically. Rebound brake mechanism by automatically controlled.

- High rigid shock table.

- Using the anvil as a vibration insulation seismic base, to reduce the vibration effect the surrounding.

Specifications

| Model | HSKT10 | G-SKT10D |

| Table size (mm) | 200 x200 | 300 x 300 |

| Specimen max weight(kg) | 10 | 25 |

| Shock pulse | Half-sine | |

| Acceleration range (m/s2) | 20-2000 | 20-10000 |

| Pulse duration range (ms) | 0.2~18 | 0.2~18 |

| Max.Drop Height(mm) | 1500 | 900 |

| Mechine Dimension(mm) | 660*700*2380 | 1350*1250*3300 |

| Utility reqyurements | AC220V 50Hz 5A Air pressure:more than 0.5Mpa | |

FAQ:

How do you attach the hardware you’re testing to your shaker?

By means of a fixture, usually aluminum or magnesium for lightness coupled with rigidity. They can be cast, or smaller fixtures machined from solid stock. Most fixtures are welded.

How do you control shakers?

If we’re looking for resonances in the product we’re testing, we command the shaker to shake the product at one frequency at a time but to vary that test frequency, to sweep it over a range of frequencies.But more realistically, we command the shaker to vibrate randomly and to excite all the resonances simultaneously.Control commands go into the keyboard of a specially-programmed computer.

What are those resonances?Are they bad?

Have you ever noticed the steering wheel moving with rather large displacement amplitude, larger than the input to the column? That magnification is called resonance. Possibly it annoys you. There’s a slight chance that in a few years that whipping of the steering column might cause bending fatigue failure.When we shake an automotive or ship or land vehicle instrument, we're looking for, for example, portions of printed wiring boards (PWBs) responding with greater motion than we're inputting. That flexing may damage PWB wiring, it may damage the attached components, and it will damage the soldered connections between components and the PWB.

Service

Pre-Sales Service

1)Technical consultation: test method, laboratory planning and suggestion.

2)Equipment selection: selection scheme, FAQ.

3)Product testing scheme.

4)Customer communication and progress report.

After-Sales Service

1)Technical training: operation of equipment, daily maintenance, common fault diagnosis and troubleshooting.

2)Scheduled on-site service: Detection of problem as soon as possible in order to eliminate equipment and anthropogenic hazards. This is to ensure long term and stable equipment operation as well as delivery of latest technical information.

3)Technical support: special paid services are provided according to customer’s needs.

Product Details